Wood Rotary Cutting Process, Ice- cream stick manufacturing process

- Model

- L520

Item specifics

- BRAND

- BESTA

- Packing

- Plywood Case

- Delivery time

- Within 15 days

Review

Description

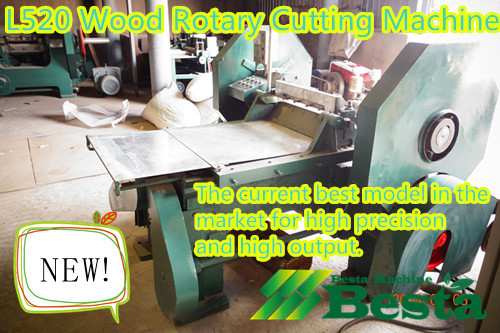

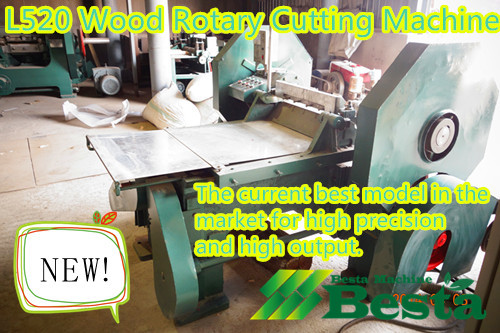

Heavy Wood Rotary Cutting Machine

L520B Wood Rotary Cutting Machine (Wooden Veneer Making ) Working Video

How to operate L520B Wood Rotary Cutting Machine

Application: Ice cream stick making, ice spoon making.

Technical Data

**Capacity: It can rotary cutting wood about 2.5 to 3 cubic meters per hour

Power: 15.5 KW

Processing Length: Max. 520MM

The diameter of the Clamp: Max. 780MM

The main axis rotating speed: 240R/MIN

Machine Size: 2500MM*2400MM*1300MM

Machine Weight: 2200 KGS

Our Machine Advantage

For our rotary machine, we improved a lot. The Max. Diameter of the wood we can process is 780mm. while other company max. Diameter is about 330mm. our machine also have good stability, the precision difference is 0.05mm. While other company is about 0.15mm. The rotation speed of our machine can reach 240 R/MIN while other company’s machine is about 163 R/MIN

Usually, the blade we equipped for customer is for processing wood max.480mm length processing. If you wish to equip 520mm length, pls

kindly let us know.

Remarks: For the whole production line introduction, welcome to email us.

Whole Production line (From wood-->dried ice-cream stick)

VIDEO LINK:

https://www.youtube.com/watch?v=Ewu1LddQplY

The process of wood rotary cutting